2 February 2017

Safety of warehouses in seismic areas?

Let us hear from the experts

The interview with Mr Tito Cudini, Head of the Technical Department of Modulblok S.p.A., during the technical conference held on January 25 in Ancona.

“Safety of warehouses in seismic zones” was the theme of the technical conference devoted to anti-seismic prevention and warehouse safety that was held in Ancona on January 25.

The panel of the event, carried out in collaboration between Hilti and Modulblok with the sponsorship of ANRA (Italian National Association of Risk Managers and Corporate Insurance Officers), included Mr Tito Cudini, structural engineer at Modulblok S.p.A., Mr Salvaterra (ANRA) and Prof. Giovanni Plizzari from the University of Brescia.

We had the pleasure of interviewing Mr Tito Cudini, who gave us interesting insights on the status of regulations (what is in place and what is missing), in what direction we are going regarding the design and how market leaders are moving to provide more reliable solutions to designers, installers and especially users who rely on such complex structures on a daily basis.Let us hear from Mr Tito Cudini.

On July 21, 2016, EN16681 came into force. It is the first European standard that provides guidelines for sizing and testing racking systems. What are the consequent changes at the design level? What are the main parameters to be considered?

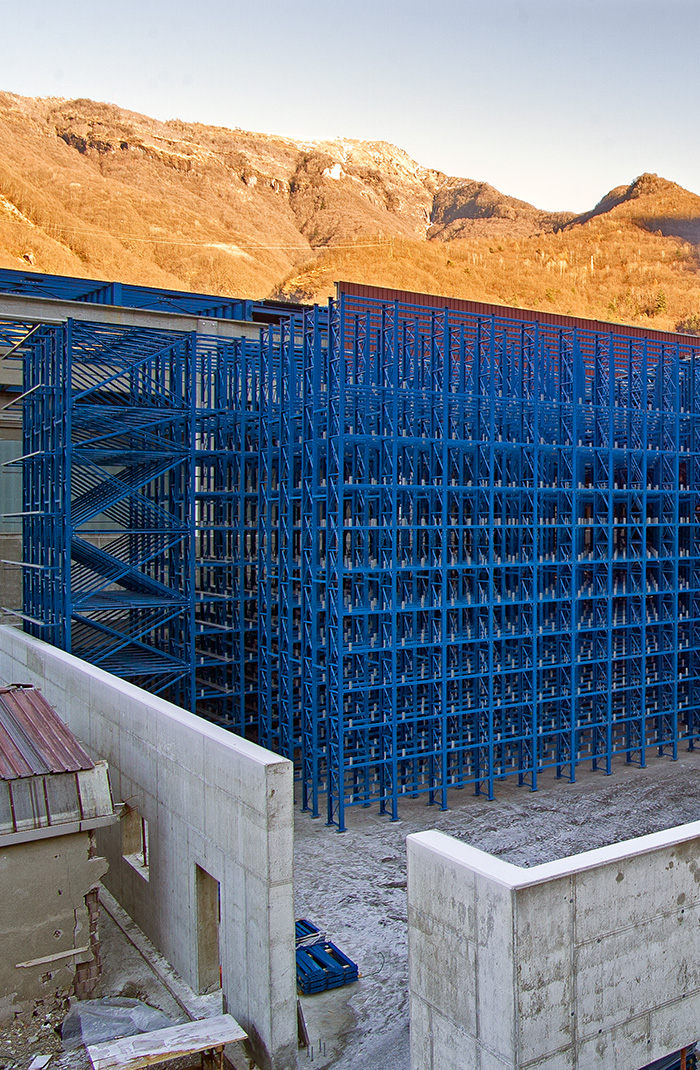

Racking systems are very special structures, not comparable to traditional steel structures, with a complex dynamic behaviour affected by the interaction between the structure and the goods. Finally there are European regulations that define precisely the seismic action to be considered for pallet racking systems. Alongside the basic information required for the definition of the seismic action for any other type of structure, such as the site of installation, reference life and type of terrain, racking systems are greatly affected by the type of goods stored, the type of pallet used, and the environmental conditions of the warehouse.

Is this the only regulatory reference available or are there other Italian regulations/guidelines that can be followed?

After the earthquake in Emilia, the Higher Council of Public Work issued guidelines on temporary safety provisions for industrial buildings, which included an important chapter on checks to be carried out on racking damaged by an earthquake. We are expecting the completion of the guidelines with additional information on the design of new racking systems and the safety of existing ones.

Given your widespread presence in the Italian territory, at what point are we, in your opinion, regarding the anti-seismic adaptation and the related awareness of the end user? What are the duties of a company like yours, always attentive to research and development?

Unfortunately, the world of special storage facilities is far behind the seismic adaptation applied, for instance, to buildings. Apparently, only 5% of the warehouses installed in Italy are designed to withstand an earthquake. This is certainly due to the fact that for decades racking systems have been assimilated more to furniture or machinery rather than being considered real structures, designed only for vertical loads without clear regulatory references. For many years, Modulblok has been trying to contribute to the definition of clear rules for the design of these particular structures, participating at the national and European level in the drafting of sectoral rules. The company’s commitment is to spread a culture of safety in logistics, showing how solutions that are only a little more expensive than those commonly used can lead to a huge drop in the seismic vulnerability of racking systems.

What is the importance of anchoring for racking? What are your criteria for choosing and designing anchors in a seismic area? Is the regulatory framework for the design of seismic-resistant anchors clear enough?

Given that racking systems are very thin and free standing structures (especially in a seismic area, they must not be connected to the walls of the sheds), proper ground fixing is essential. The racking sector has always used post-installed fastening systems, for their flexibility and ease of use. Recent regulatory developments in the anchoring sector have led to a rapid evolution, increasingly oriented towards the use of chemical fixings, which can guarantee high performance against the considerable traction that can be generated at the base of the racks due to an earthquake.

On 25 January, you were the protagonist, along with Hilti and ANRA, of an event focused on raising awareness regarding anti-seismic prevention. What was the goal of the event? What are the main topics you have discussed and what prompted you to choose Hilti and ANRA as “travel companions”?

We want to demonstrate to a group of representatives of companies, control institutions and logistics consultants, that designing and building seismically safe structures, in a country characterised by high seismic hazard, is necessary, possible and has a reasonable cost. For too long the vulnerability of storage facilities has been underestimated and it is now necessary to ask how much people who work in warehouses and access their spaces and stored goods are really safe. Hilti has long been a valuable partner for Modulblok, considering the high quality of its products, its valuable after sales service and the continued pursuit of excellence in the safety of anchoring systems. The meeting with ANRA becomes fundamental to measuring the risk associated with the use of extremely vulnerable structures and, at the same time, indicating possible and economically reasonable solutions to increase the safety of installations and people in the logistics world. The conference will therefore address all the structural issues related to racking safety, starting with the correct design and construction of the industrial floor (which will see the contribution of one of the top experts at the international level), and looking at the storage system and finally at the metal structure of the rack.

Is Ancona a fortuitous choice or is there any clear motivation behind it?

In a time of anguish and loss for the repeated seismic events in Central Italy, we want to contribute to a virtuous path that makes prevention the main tool to deal with seismic emergency, giving certainty and safety to those who work and invests in the logistics world.

Thanks to Mrs Maria Teresa Intorre for the collaboration and Mr Tito Cudini for his kind contribution.

Article published on February 2 by HILTI ITALIA